Process

Transforming ideas into high-quality garments through precision, innovation, and care.

Contact UsOur Process

Every step counts in delivering the highest quality garments for you

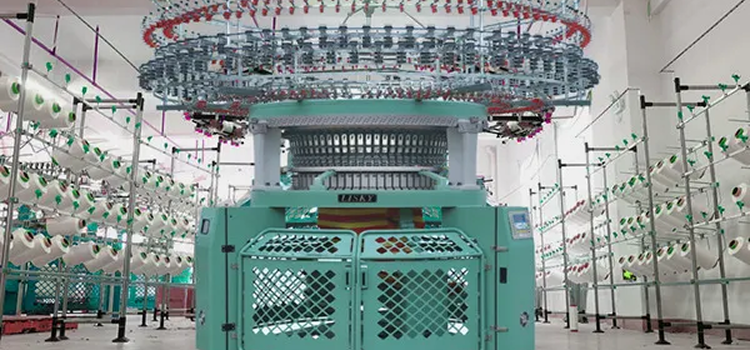

Knitting

Knitting is the process of interlocking yarns to create fabric that is soft, stretchy, and comfortable. This technique is commonly used in the production of garments like t-shirts, sweaters, and activewear. The fabric produced through knitting offers excellent flexibility and breathability, making it ideal for everyday wear. The process also allows for various textures and designs, enhancing both function and style in the final product.

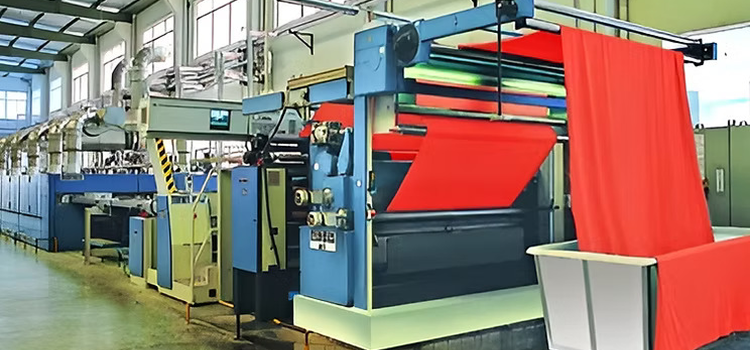

Dyeing

Dyeing is the process of adding color to fabric, ensuring it reaches the desired shade. This step is key for achieving vibrant, consistent colors across all garments. Different dyeing techniques are used based on the fabric type and desired finish, from rich, deep hues to subtle tones. Proper dyeing also helps in making the fabric more resistant to fading, ensuring the garment retains its color after washing.

Compacting

Our process transforms raw materials into high-quality apparel with precision at every step. Starting from yarn, we knit, cut, sew, and dye to create the perfect garment. With advanced printing and embroidery, we add intricate designs and finishes. Finally, rigorous quality control ensures each piece meets our high standards before it reaches you.

Printing

Printing is the technique used to apply intricate designs, logos, or patterns onto fabric. This can be done using various methods such as screen printing or digital printing. Printing allows for unique designs and detailed graphics, which can be used for branding, artwork, or decorative patterns on garments. The process ensures sharp, clear prints that withstand wear and washing without fading.

Embroidery

Embroidery involves stitching decorative designs into the fabric, adding texture and visual appeal. This technique is often used for logos, intricate patterns, or embellishments on garments. Embroidery can range from simple monograms to complex, multi-colored designs. This process elevates the garment, making it look more sophisticated and unique, often used for premium or customized pieces.

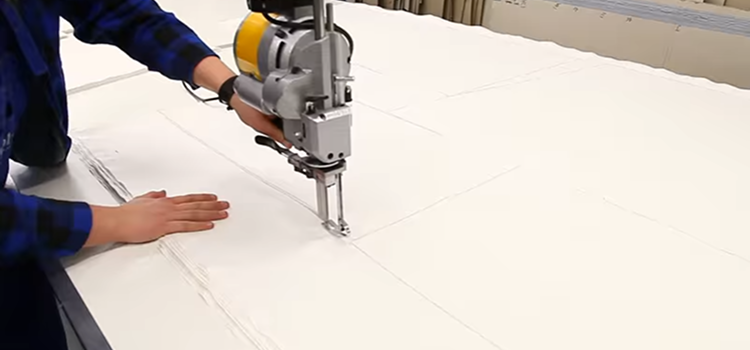

Cutting

Cutting is the precise process of shaping fabric according to a specific pattern or design. After the fabric is dyed and prepared, it’s cut into the necessary pieces required to assemble the final garment. This step ensures the fabric pieces fit together perfectly, minimizing waste and allowing for a consistent end product. Precision during this stage is crucial for maintaining the intended fit and overall design integrity.

Stitching

Stitching is the critical step where cut fabric pieces are joined to form a complete garment. Skilled workers use advanced sewing techniques to ensure precision and durability in every seam. Whether it's a basic stitch or intricate details, stitching enhances both the functionality and aesthetic of the garment. The process guarantees that each piece fits perfectly and meets high-quality standards for comfort and longevity.

Checking

Checking is an essential quality control process in garment manufacturing. It involves thorough inspections at various stages to ensure that the garments meet the required standards for size, stitching, and finishing. Skilled inspectors carefully check for any defects such as misalignment, loose threads, or fabric inconsistencies. This step ensures that only flawless products make it to the next stage of production or shipping. A detailed checking process guarantees customer satisfaction and minimizes returns.

Ironing

Ironing is the final step in garment finishing that ensures a crisp, polished appearance. During this process, garments are carefully pressed to remove any wrinkles or creases that may have formed during manufacturing. It helps restore the fabric’s smooth texture and enhances the garment's overall presentation. Proper ironing also improves the fit and gives the fabric a fresh, ready-to-wear look. This step is crucial in ensuring that the garment looks professional and meets customer expectations.

Packing

Packing is the final step in the garment manufacturing process, where finished garments are carefully folded, sorted, and packed for delivery. This stage ensures that each item is securely packaged to prevent any damage during transit. The packing process includes labeling, tagging, and placing the garments in protective packaging, such as plastic bags or boxes. It’s essential for maintaining the quality and presentation of the garments. Proper packing helps in ensuring that customers receive the products in pristine condition, ready for sale or use.

Our Services

Discover the wide range of solutions we offer to meet your needs, from web design to marketing strategies.

Design and Development

We prioritize understanding client needs, fostering long-term trust. Materials are sourced only after thorough verification to meet exact specifications. Beyond standard offerings, we explore new possibilities, introducing fresh ideas to enhance products.

- Client-Centric Approach

- Thorough Cross-Checks

- Innovative Options

Call To Action

Transform your ideas into premium garments with our expert craftsmanship. Let’s create something extraordinary together!

Call To Action